© Susan Louise Moyer 2015

HOW TO MAKE YOUR OWN ACID DYE-CAKE PALETTE

Dye-Cake Palette (gum arabic and glycerine)

When liquid dye is solidified into a concentrated dye-cake, the artist is able to control the amount of liquid being picked up by the brush and the amount of water on the painting surface. This control gives the artist the ability to create a variety of wonderful effects. Many of the effects are unique to painting directly on gutta treated silk (dye-colour painting) while others are similar to the effects achieved when using transparent watercolor on hot pressed watercolor paper or a slightly slippery surface such as Aquabord and Bristol Plate.

Some additional benefits of working with dye-cake palettes are that they can be used with gutta-serti techniques as well as with other resists. They come in handy when color mixing and applying color in small areas. They eliminate the small mixing cups and wasted dye, keeping your studio organized and mixing process efficient. Surprisingly, you will discover that concentrated dye-cakes last quite awhile before your frequently used colors need replenishing.

Setting Up a Studio Palette

You can work with the mixing colors suggested below and/or customize a palette by choosing colors from a manufacture's line of liquid acid dye (Tinfix Design, H. Dupont). You can also mix a color such as paynes grey and windsor red or lipstick-red and then make it into a dye cake. I have participated in transparent watercolor classes where instructors require specific colors for the class. I had the instructor send me a sample of these colors on watercolor paper. I then mixed my dye to match the colors samples and made my dye-cakes accordingly.

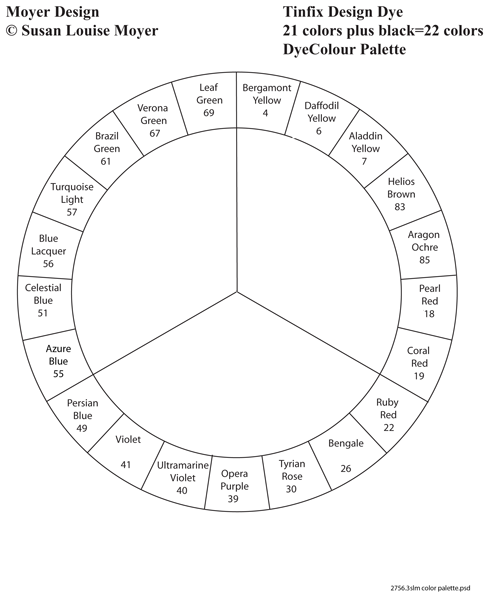

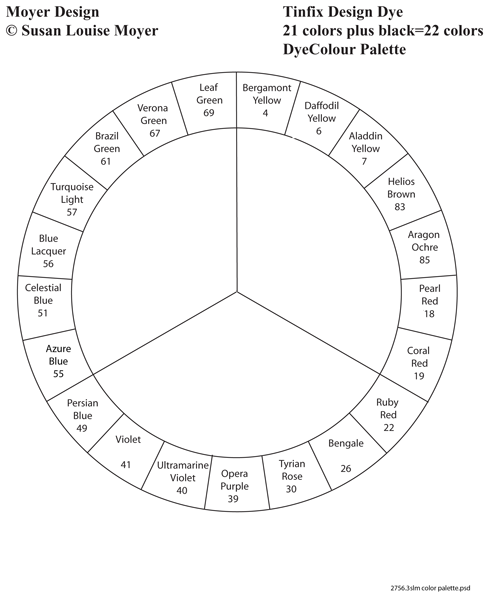

ColorWheel Palette (21 Tinfix Design Dyes plus Black)

When painting in my studio, I work with a ColorWheel palette because the format is a guide for color theory. I load the palette with a set of warm and cool primary colors for color mixing, secondary colors, and for convenience I load the rest of the palette with colors that cannot be made from the primaries and colors I use most frequently. Black is kept in a separate container.

The ColorWheel Palette has 21 wells divided into three sections of seven colors each and a handy lid with additional wells and sections for color mixing.

Section 1: Yellow - Red Orange

04-Bergamot Yellow*

06-Daffodil Yellow

07-Aladdin Yellow*

83-Helios Brown

85-Aragon Ochre

18-Pearl Red

19-Coral Red*

Section 2: Red - Red Blue

22-Ruby Red

26-Bengale*

30-Tyrian Rose

39- Opera Purple

40-Ultramarine Violet

41-Violet

49-Persian Blue

Section 3: Blue - Yellow Green

55-Azure Blue*(substitute for

discontinued 54-French Blue)

51-Celestial Blue

56-Blue Lacquer

57-Turquoise Light*

61-Brazil Green

67-Verona Green

69-Leaf Green

For 104-Ebony Black, use the wells of the lid on the ColorWheel Palette or a separate small plastic container with a lid.

Corresponding numbers refer to a specific Tinfix Design color.

* denotes working primary color

Transform Liquid Dye into a Dye-Cake (solid consistency)

To make liquid dye into a dye-cake, gum arabic powder and glycerin are added. The gum arabic powder, which is a water-soluble binder, helps form a cake. Glycerin, a humectant and a plasticizer, prevents the cake from becoming brittle. This mixture of liquid dye, gum arabic and glycerin is the dye-cake stock. Dehydrating the stock into a dye-cake is the step that produces the rich concentration of color necessary to control wet-in-wet techniques as well as many other transparent watercolor techniques. A light spray of water can be used to activate a dye-cake palette or a wet brush can be used to easily activate an individual dye-cake color.

Dye-Cake Stock and Palette

|

Equipment needed to make dye-cake stock and dehydrate the stock into dye-cakes in a ColorWheel Palette. |

Ingredients:

1. Gum arabic powder is a natural gum made of sap harvested from the Senegal species of the acacia tree. It is used as a binder in cooking as well as in products for making art.

Note: Refined gum arabic powder used to bind watercolor pigments melts easily. Consequently it does not bind dye well. The dye-cakes slump and melt.

Natural Products Co Op, www.frontiercoop.com, 800 669-3279

2. Liquid acid dyes

Tinfix Design Dye: (suggested 21 colors plus black listed on page 3)

Please note that I am working on a formula for Jacquard Red Label Dyes and will be sharing what I glean from my experiments.

3. Glycerin (vegetable or animal glycerin):

Natural Products Co Op, www.frontiercoop.com, 800 669-3279

US and Canada +1-707-459-9998 OR pharmacies and health food stores

Equipment and supplies:(to make 1 ounce of dye-stock)

• 24 one-ounce Nalgene bottles with leak proof caps.

http://www.freundcontainer.com/leakproof-plastic-bottles/c/44/

• Labels for Nalgene bottles

• Funnel that fits into the mouth of the Naglene bottles

• Electric heating pad (dry heat, flat - for melting the gum arabic and dehydrating the dyecake in the palette): Sunbeam Heating Pad model 749-811-825. For our purpose this convenient model does NOT automatically turn off in 30 minutes.

• Tray to place the containers of dye-cake stock on top of the heating pad

• Measuring spoon(s) (1 teaspoon, 1/2 teaspoon)

• Worktable covered with plastic for easy clean up

• Nitrile or latex gloves (Kirkland multi-purpose exam gloves)

• Permanent black Sharpie marker with a fine point for labeling palette and bottles

• Isopropyl alcohol and Q-tips to remove black marker from palettes if needed

• Optional:140-pound cold pressed watercolor paper for making color charts and color notes

• Studio palette suggestion: ColorWheel Palette with 21 wells and lid plus one small separate container for black.

• Silica gel packs for keeping a palette dry. (I save the silica gel packs I find in food boxes and store them in a sealed plastic bag.)

Basic Dye-Cake Stock Recipe (to make 1 oz of dye-cake stock)

• 1 oz of Tinfix Design dye (One ounce provides enough dye-cake stock to fill one 1/4 oz. well in a ColorWheel studio palette and to fill pans for a plein-air palette and extra for refills.)

• 1 level teaspoon gum arabic (gum powder) used to thicken the dye

• 0-2 drops of glycerin, to use as a plasticizer to prevent cracking and brittleness. Amount varies per color.

Note: Since colors have different chemistry they behave differently. Consequently, there are colors in the Tinfix Design line and other brands of liquid acid dyes that may require additional gum to bind or more glycerin to keep the cakes from cracking or less to keep them from slumping and running. (See note under number 2 below.)

Process for making Dye-Colour Stock (1 ounce)

|

Dye, gum arabic powder, glycerine and the equipment needed to make dye-cake stock. |

1. Choose the colors according to the palette you plan to set up. Label each Nalgene container with the name of the dye, date and recipe.

2. Using the funnel, measure the gum powder into the 1-oz container.

Note: There are three Tinfix Design colors recommended for the ColorWheel Palette that require 1 1/2 teaspoons of gum arabic per one ounce of dye instead of 1 teaspoon, and only 1 drop of glycerine if any. These colors are 4-Bergamot Yellow, 61-Emerald Green and 104-Ebony Black.

3. Shake the bottle of dye. Then pour the dye into the one ounce container leaving room at the top to later shake the added ingredients.

Note: Dye bottles needs to be shaken before pouring. Otherwise chemicals that have settled to the bottom may become concentrated making the remaining dye in the bottles unpredictable and harder to solidify.

Yellow and colors that contain yellow may be blobby and not combine well. Warming these colors on the heating pad will help dissolve the jello like consistency for easier mixing.

4. Add 2 drops of glycerin (0-1 drop in 4-Bergamot Yellow, 61-Emerald Green and 104-Ebony Black), cap and shake.

|

A tray of Nalgene bottles containing the dye-cake stock are being warmed on the heating pad to melt the gum arabic. |

5. To melt the gum Arabic, place the container(s) of dye-cake stock on a tray on the heating pad and cover lightly with foil or a box to hold in the heat. Shake occasionally. It may take a few hours or overnight for the gum to melt.

|

Optional: To hold in the heat and speed up the melting process, aluminum foil is used to cover the bottles of dye-stock. |

6. Once you have made the dye-cake stock you are ready to load your palette.

Dye-Cake Palette

Loading the Palette with Dye-Cake Stock

1. Following the chart below, write the colors on the outer rim of the palette with a fine black permanent maker.

|

The palette is placed on the heating pad and the dye-cake stock is loaded into the well. The dye-cake stock is then dehydrated into dye-cakes on the heating pad. |

2. Place the palette directly on the heating pad and carefully pour stock into each well.

Reminder: Before proceeding vigorously shake the dye-cake stock. Check the bottom of the bottle for translucency so you know the gum is melted and has not settled on the bottom of bottle.

3. Let the dye-cakes dehydrate overnight or until dry. Be aware that some heating pads automatically turn off after 30 minutes.

Note: As the dye-cakes dry, some will look smooth and shiny others will look rough and/or bumpy and some colors take longer to dry than others. This is the normal behavior for individual colors and does not affect the quality of the color.

Note: Proper ventilation is always a good idea when working with dyes. The times to use ventilation are when the dyes are being applied and drying on the silk, when using a hairdryer to control technique and drying painted silk, when making dye-cakes and steam setting the dyes.

Always wear gloves when pouring and mixing liquid dyes.

4. If a color develops a pudding skin that traps moisture, break the skin with a tooth pick to encourage quicker drying.

5. Optional: Once the colors have dehydrated, leaving room in the wells or pans, you can add more stock solution.

|

When the dye-colour stock in each well is completely dehydrated, the dye-cake palette is ready for use or to be covered with the lid. Under humid as well as damp conditions the dye-cakes may absorb moisture and start to sump and run. Therefore silica gel packs have been placed in the palette to help prevent the dye-cakes from absorbing moisture. |

6. Once the dye-cakes are dehydrated and dry, remove the palette from the heat. Let it cool briefly before covering it with the lid.

Notes:

A. Store your palette with two or three small packs of silica gel to absorb moisture. Gently heating silica gel packs on a heating pad will drive off the adsorbed moisture and leave it ready for reuse.

B. If a color does not harden, the dye-colour stock may need more gum powder and less glycerine. First warm up the dye-cake stock. Scrape the color out of the palette into the small plastic cup and add just enough warm stock to make the mixture more liquid. Then slowly add 1/2 teaspoon of gum arabic powder and mash with a stencil brush until it becomes a smooth slurry. Pour it all back into the warm dye-colour stock. Note the recipe change on the label, shake and refill the pan or well and allow it to dry.

C. If over a couple of months time the dye-cake becomes so brittle that it lifts from the well, adjust the formula by adding glycerine to the dye-cake stock. If a dye-cake runs, add more gum arabic and less glycerine. Update the formula on the label.

7. Once you have set up a palette, execute a corresponding color guide on 140-pound cold pressed watercolor paper or on silk. If using silk you will need to steam set the dye.

Storage and Shelf Life of Stock and Dye-Cakes made with Tinfix Design and H. Dupont acid dyes

Dye-cake stock and dye-cakes made with gum arabic have an excellent shelf life. Mine have lasted over eight years. Over time you might see some of the dye-cakes crack but they will still be fine to use. Store the stock and palette at room temperature out of the direct sunlight.

To remove and keep moisture out of the palette, especially for travel, place the palette on the heating pad. When dry, place two or three silica gel packs in the palette before closing the lid.

For travel, seal the ColorWheel palette and lid together with plumbers tape.

|

|